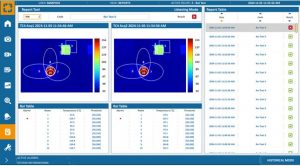

In 2025, Marposs will introduce the next generation of the Total Thermal Vision (TTV) system, a significant evolution in thermal control for die casting processes. The third generation of TTV will be able to detect the surface temperature of the mold with greater precision, thanks to the introduction of a new thermocamera developed in-house by Marposs and an even more advanced, user-friendly data interface and management software. The innovations introduced leverage Marposs’ decade-long experience in the die-casting sector, with over 250 systems sold globally and a strong presence in cutting-edge projects at the international level. The new generation is designed as an indispensable tool to optimize the spraying phase and thermal regulation, reducing defects related to thermal irregularities, improving product quality, and enhancing the overall OEE (Overall Equipment Efficiency) of the plant.

The challenges of modern die casting, particularly with the advent of large machines and the phenomenon of “giga casting,” demand automatic and intuitive thermal control for the operator. Over the years, TTV has supported numerous projects where the high added value of individual parts justified the system’s introduction just a few months after installation. Additionally, starting in 2025, the TTV product line will expand, offering more scalable and modular solutions tailored for small, medium, and large presses, depending on the required accuracy, integration with the press, and the number of thermocameras involved.

Thanks to these innovations, Marposs will ensure greater efficiency, reduce operational costs, and optimize the production cycle, also positively impacting waste reduction and energy sustainability.

Digitalization in Foundries: The Key to Improving Production

In addition to the mechanical and structural innovations shaping the sector, digitalization is the next challenge that every entrepreneur must address to stay competitive. The integration of advanced systems like the Manufacturing Execution System (MES) and the Industrial Internet of Things (IIoT) enables real-time monitoring of production processes, improving quality, productivity, and traceability. In this context, TTV integrates seamlessly with MES, allowing the real-time archiving and analysis of thermal data, enabling timely interventions in case of anomalies.

Digitalization also opens the door to using technologies like artificial intelligence (AI) to optimize processes with high scrap rates and in situations where reliance on individual operator know-how is no longer sufficient. The data collected by TTV and other peripheral devices on the press become indispensable tools for supporting decision-making, aiming to reduce downtime and improve operational management especially during warm-up and mold change phases. Furthermore, these solutions contribute to greater sustainability by optimizing resource use and reducing energy consumption, aligning with the goals of a circular economy.

Marposs is strongly committed to supporting the digital transition in manufacturing. With its experience in the automotive and machine tool sectors, Marposs positions itself as a pioneer in introducing digitalization to the die casting industry through systems like Total Thermal Vision. The combination of automation, AI, and data control is critical to facing the future challenges of die-casting, making foundries smarter and better equipped to adapt to the needs of an ever-evolving market.